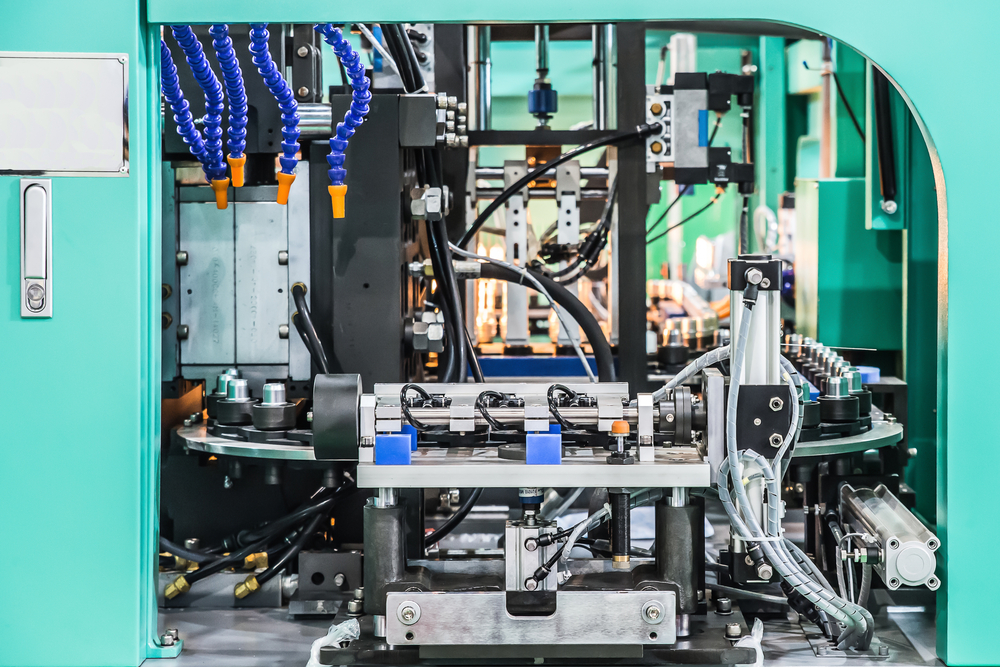

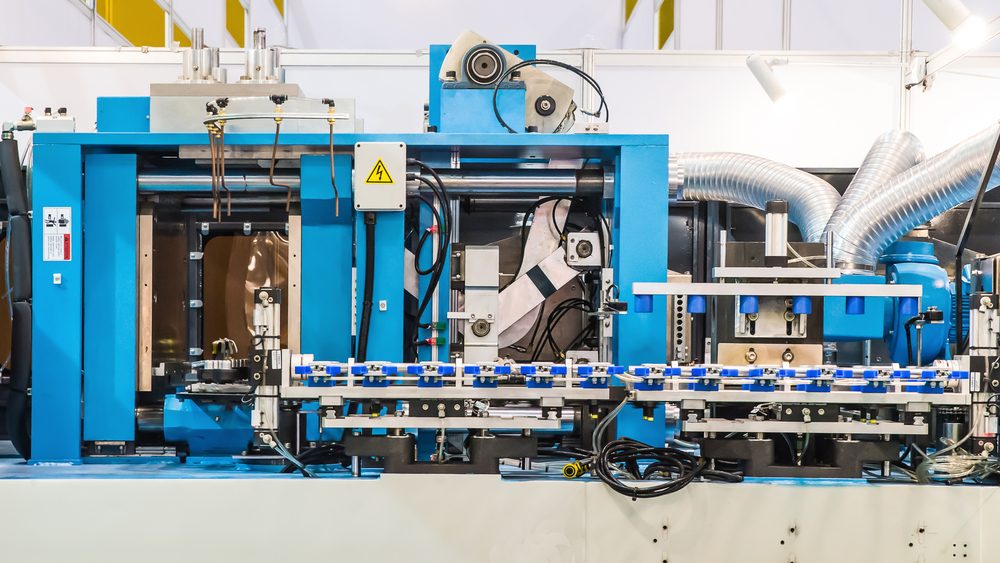

Blow Moulding Technology

We are happy to provide you with our expertise in the field of extrusion blow molding. This concerns the technology of the extrusion blow molding machine for the production of hollow plastic parts such as bottles, canisters, air ducts as well as the complete periphery for the post-processing of the hollow plastic parts.

Engineering for complete plants for the production of plastic hollow bodies

Companies engaged in the production and filling of various engine and transmission oils, antifreeze, windshield cleaners or various other liquids or suppliers of technical parts for the automotive industry are among our customers. Our customers produce the parts in the form of blown bottles, canisters, air guides made of plastic on their own extrusion blow molding lines. Likewise, the corresponding plastic closures are produced by injection molding. Post-processing, packaging, palletizing, quality control, logistics, etc. are also important components in the production process of our customers.

We, Sagittarius Engineering GmbH, offer our customers complete engineering for new production lines or optimization and reconstruction of existing production lines for the purpose of improving production processes, reducing internal traffic, bundling the supply of all machines with raw material, (HDPE, LDPE) compressed air, cooling water and electrical energy.

The engineering services offered by us are divided into several sections due to the complex scope of tasks:

- Preparation of the basic documents as basis for the different planning stages

- Planning and design of the machine installation (plastics processing, compressed air supply, cooling water production and raw material supply)

- Planning or modernization and automation of article handling behind the article removal of the blow molding machine

- Modernisierung und Automatisierung des Artikelhandling hinter der Artikelausgabe der Spritzgießanlagen

- Preparation of the project documentation

If you have any questions about blow molding machine technology or blow molding part development, you've also come to the right place.